The process of vapor honing involves the abrasive sanding of surfaces to produce the highest finish possible. There are many benefits of a vapor honing machine. It is a non-destructive process that can be used on a variety of surfaces, from glass to metal. It is an ideal choice for high-end metal and wood finishing applications. The machines produced by vapor honing technologies are designed and manufactured in the United States, and their products are supplied to most major markets.

Vapor honing machines use water and abrasive materials to clean surfaces. The mixture combines the abrasive materials to produce a scrubbing action that smooths the surface. The mixture is rinsed off by the water and can be used to treat a variety of materials. As with dry-blasting, the slurry mix is also recyclable, which makes it an excellent choice for industrial applications. Kindly click and learn more about vapor honing technologies.

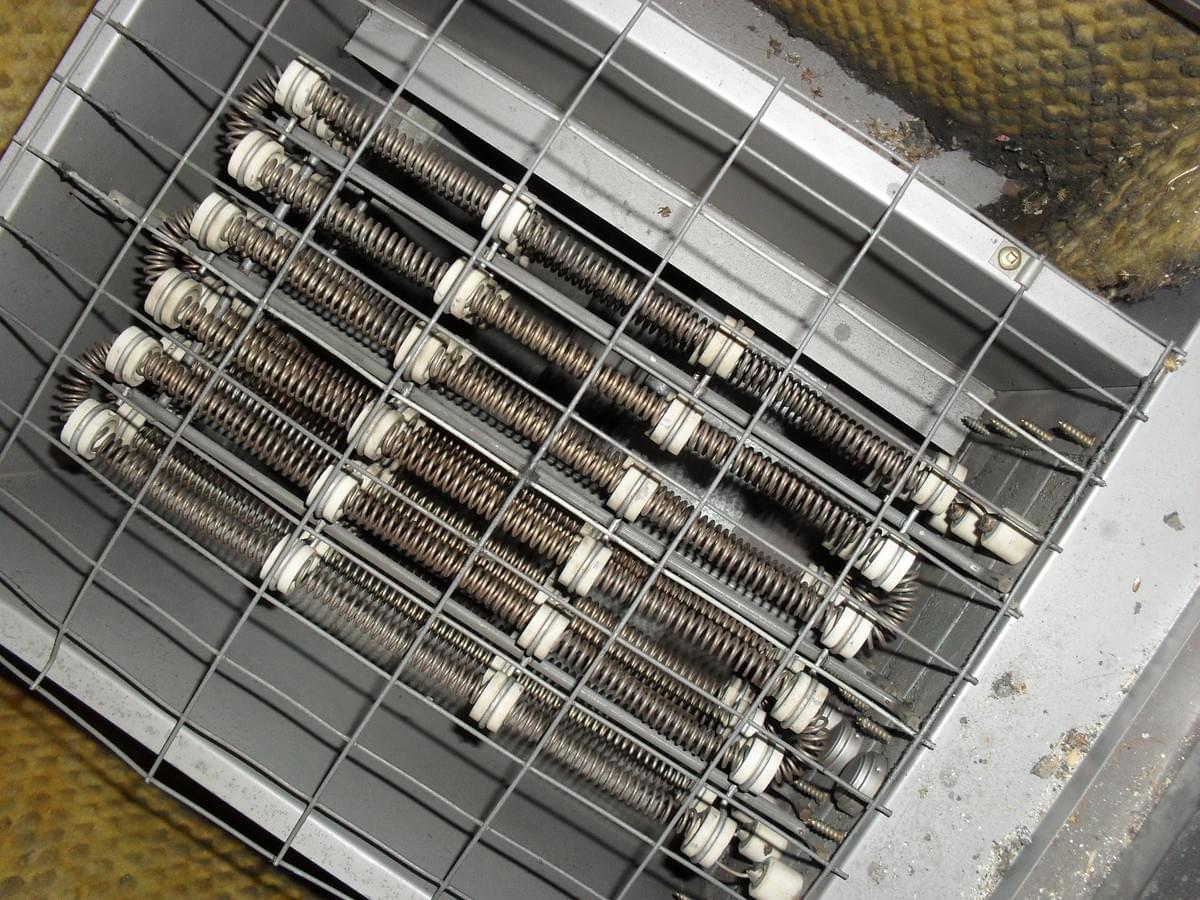

Vapor honing machines can be very effective for certain types of surfaces. Dry-blasting, for example, can leave a dusty residue behind. The process is often unsuitable for parts made of steel, but it is a great option for parts that must be sanded after machining. It is particularly beneficial for cleaning motorcycle components. Unlike dry-blasting, vapor honing machines can be used on sensitive surfaces, such as internal engine parts and carburetors.

A vapor-honed finish is a beautiful, smooth, and shiny surface. It is a great choice for many different parts. It is often applied to metals and plastics. It can also be used to clean electrical connectors, PCBs, and metals. It is a versatile technique that is applicable to a number of different industries. For example, vapor-honed surfaces are smoother than finished items.

The process of vapor-honing is a good alternative for dry-blasted parts. Due to the fact that it uses water in its slurry mix,why vapor honing technologies is more affordable than dry-blasted parts. It is also applicable to a variety of parts and can be done in-house. Aside from cleaning, vapor-honing machines can also be used to clean electrical connectors. A slurry blasting is similar to vapor-honing, but with more pressure, it is more effective.

When a slurry mix is applied to a surface, it is abrasive. This means that abrasive particles are removed and the surface is smoother. This method is an excellent choice for sensitive surfaces, including fire-damaged walls. It is effective, but should be used carefully. The process is highly sensitive, so it is important to use a water-based slurry to reduce the effects of abrasive material.

A wet-blasting machine is a popular choice for removing rust from metal parts. The process can be used on almost any surface, including plastic. In addition, it can produce a high-quality finish on both metal and glossy surfaces. This process is often preferred by automotive manufacturers, as it reduces downtime. This method is also effective for preventing rust and corroding parts. It provides a more durable finish than dry-blasting. Find out more details in relation to this topic here:https://en.wikipedia.org/wiki/Vapor_polishing.